3D Printed Tensegrity Soft Robots

Additive manufacturing and tensegrity and robots? Soft ones? These are three of our favorite things.

A South Korean research team from Ulsan National Institute of Science and Technology, has combined all three of those components into one project, in the form of a robotic starfish that moves just like a real one (kinda).

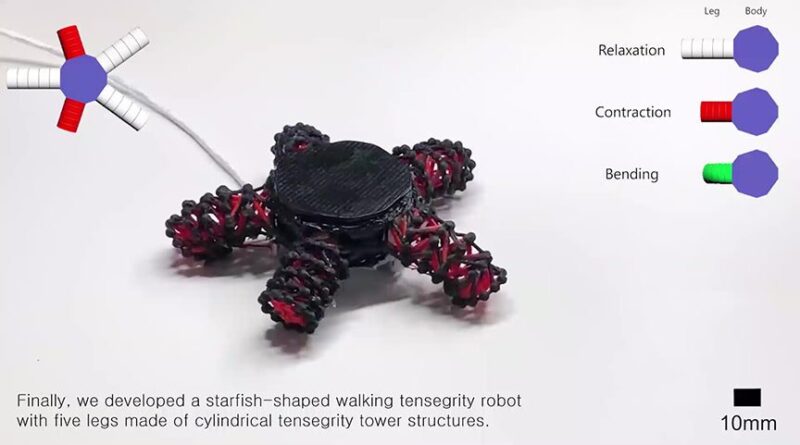

You can see the little robot in the above image. Note the mesh-like structures in the legs of the starfish. Those are the tensegrity parts.

It achieves this feat of biomimicry by use of tendons arranged as a tensegrity structure. That is, a structure that is undergoing compression by virtue of a network of members in tension.

You may have seen the effect in various works of art, or even on social media recently, as people have been using tensegrity principles to design artworks and trinkets.

If an image is worth a thousand words, then hopefully this video can demonstrate the concept of tensegrity a lot quicker than our word count will allow. Note in the video that the entire structure seems to be in compression on those thin threads, which seem to be miraculously standing rigid as the weight bares down on them. But they aren’t in compression: they are in tension. It all balances out.

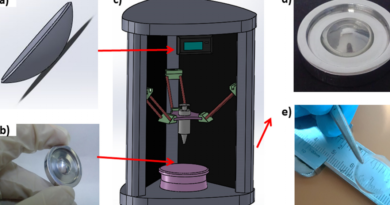

In the case of the starfish robot, these tendon networks have been created by use of a 3D printed sacrificial mold. The mold is printed with the cavities for the tendons and the rigid structures. When the mold is complete a resin is injected into the mould, and when the tendon network has cured, a dissolving agent is used to dissolve the mold, leaving only the network of tendons and rigid members remaining. The graphic below explains that.

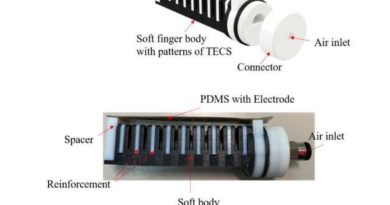

Cobots (collaborative robots) are also getting more “softer”, as it is a health and safety requirement to not have humans working next to robots with hard mechanical limbs flying around. There is ongoing research into soft-graspers as well, which fit onto traditional (hard) robotic arms, and provide a dynamic end-effector that can mold its shape to a variety of geometries compared to a traditional robotic “claw”.

Source:https://3dprinting.com