Why Companies Steadily Embrace Additive Manufacturing

3D printing technologies have a wide range of benefits over subtractive and formative manufacturing techniques.

The 3D printing revolution is slow and steady but has the potential to be highly disruptive.

This transformative approach to industrial production allows engineers to rapidly create prototypes and sometimes lighter and stronger parts, at a fraction of the cost compared to more commonly used subtractive manufacturing methods. Logically, individuals, companies, and institutions are drawn to this value proposition.

The 3D printing, or additive manufacturing (AM), market was valued at $13.7 billion in 2019, 14.4% higher compared to the previous year. Various estimates have the emerging industry slated to reach a market value of approximately $41 billion by 2026.

Driven by the automotive and aerospace industries, engineers are exploring various ways to integrate 3D printing technologies into workflows. Automotive leaders like Bugatti have used AM to print some parts for flagship vehicles. Boeing and Airbus have also been using AM technologies to develop and produce some parts for their airplanes, satellites, and helicopters.

Apparel companies Adidas and Nike are using 3D printing technologies to push the production volume of some of their most ambitious sneaker designs.

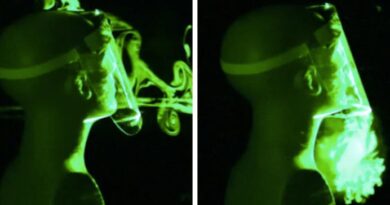

Restaurants are exploring various ways to print food and even beverages. Medical professionals are beginning to print functioning organs and organoids. And this is only the beginning.

Additive manufacturing has already infiltrated just about every major industry. However, although the technology offers engineers some exciting workflow benefits, AM does have its limitations.

Today we are going to look at how some companies are using additive manufacturing, as well as the limitations of this revolution. But first, what is additive manufacturing?

Will 3D printing remove traditional manufacturing all together? No. Additive manufacturing will not replace CNC machining or Injection Molding. Global manufacturing is currently valued at $12.7 trillion. This means AM represents less than 0.1% of global manufacturing. The technology’s limitations will likely keep it within the boxes of low-production manufacturing and prototyping.

However, this does not make the technology any less disruptive. If anything, 3D printing technologies have already found a permanent home in the aerospace, medicine, and automotive industries.

This technology will likely be used alongside more traditional manufacturing methods to create a digital manufacturing ecosystem in the coming decade.

Source:https://interestingengineering.com