Researchers Develop Sweet New Way of 3D Printing Vascular Networks

Researchers from Rice University have developed a new method of using 3D printing to create artificial vascular networks from powdered sugar.

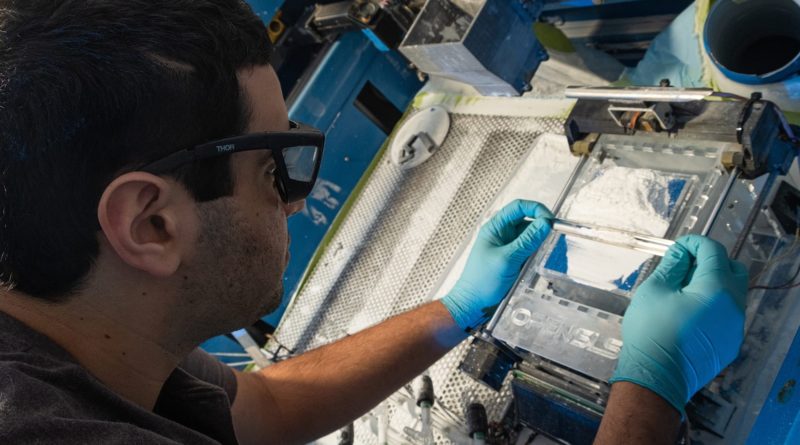

Replacing traditional production methods with Selective Laser Sintering (SLS) 3D printing, the team created sacrificial templates made from laser-sintered carbohydrate powders. These sugar-based constructs enable cell-laden hydrogels to be patterned with dendritic vessel networks, without the use of support materials. The newly-devised technique could improve the speed and scale of biomaterial production.

“One of the biggest hurdles to engineering clinically relevant tissues is packing a large tissue structure with hundreds of millions of living cells,” said Ian Kinstlinger, lead author and graduate student at Rice’s Brown School of Engineering. “Selective Laser Sintering gives us far more control in all three dimensions, allowing us to easily access complex topologies while still preserving the utility of the sugar material.”

Isomalt, a sugar-alcohol commonly used in sugar-free lozenges, was found to be compatible with SLS, and the team devised a workflow for automated fabrication of 3D structures from isomalt powder. While it would have been possible to sinter a single layer of pure isomalt, the powder’s strong cohesion and relatively poor flowability made it badly suited for spreading into smooth, thin layers as required. Further mixing the powder with cornstarch was found to effectively augment the powder’s flow while preserving sintering quality. Using this concoction, the research team successfully fabricated structures with 3D branching and unsupported geometry.

A range of additive manufacturing techniques have been developed by companies and researchers in recent years, with the goal of producing vascular-like structures. Researchers from The University of Nottingham and Queen Mary University of London for instance, have 3D printed graphene oxide with a protein which can organise into structures that replicate vascular tissues.

Boston University College of Engineering scientists on the other hand, developed a new method for treating ischemia, by 3D printing a vascular patch which encourages blood vessel growth. The patches were tested on rodents, and were proved capable of transporting nutrients around their bodies.

Swedish manufacturer CELLINK and Texas-based biomanufacturing company Volumetric, meanwhile, introduced a 3D printer, which is designed to produce large vascular structures. The Lumen X Digital Light Processing (DLP) bioprinter works with bioinks to print high-resolution, macroporous, and vasculature structures.