Avular designs custom drones from the ground up with 3D printing

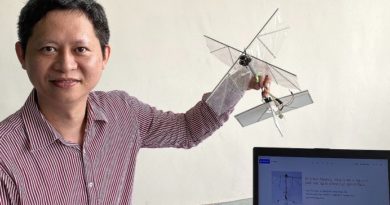

Avular plans to bring to market “The Essentials,” customizable hardware and software components that enable customers to make any kind of drone or robot they need. At its core is a series of 3-sq.-in. circuitry modules that can be clicked together on a drone or robot of any size, then custom programmed for any job. The Essentials are building blocks for mobile robotics, according to the company.

The Essentials includes a real-time, on-board computer known as the Avular Prime, which is set to launch this September. Prime is designed to enable engineers to use a USB or wireless connection to program and control mobile robots.

Cerebra, also launching in September, will enable engineers to monitor and adjust software in real-time and integrate with MATLAB Simulink, a common engineering platform, adding even more accessibility, said Avular.

One inspiration for Avular’s change in business plan toward customizable, scalable solutions was Hadek, a Dutch company that makes high-tech glass blocks to line massive power plant chimneys. Hadek came to Avular looking for a drone that could inspect its chimney linings—a necessary part of regular maintenance. “This was a very difficult challenge,” said Maas.

The chimneys can be 500 ft. tall and contain as many 90,000 glass blocks — each one requiring up-close inspection. Moreover, the thick chimney walls and narrow space eliminated the possibility of GPS guidance. And the chimneys are far too tall for even a skilled drone operator, situated on the floor in the center of the chimney, to guide the drone by sight. If that wasn’t difficult enough, Hadek required the drone to be outfitted with a heavy, specialized camera — and weight is the enemy of drone flight.

With a lot of help from sonar guidance systems, and prototyping with HP 3D printing, Avular rose to the challenge — and came away with a Eureka moment.

“We decided the most practical way to grow our business would be to create both software and hardware platforms that can be easily and quickly adapted to new applications,” said Maas. “That’s very important in an emerging market where everybody is still looking at what they can do with drones.”

But while many of Avular’s clients have their own talented engineers, they don’t know much about drone programming, which requires highly specialized coding skills. But most engineers today are comfortable programming in MATLAB Simulink. In its new components, Avular translates complex robotic software into MATLAB Simulink algorithms, making them easily usable by their customers’ engineers.