Penn State Researchers Develop Novel Process Planning Software for Support-free 5-axis 3d Printing

A duo of researchers from Pennsylvania State University have developed an automated process planning software specifically for five-axis additive manufacturing.

The program is driven by algorithms designed to automate the slicing process, leveraging the power of five axes and ensuring support free 3D printing. Xinyi Xiao cites time and cost savings as the primary motivation for the work, which she submitted as part of her doctoral program under the supervision of Sanjay Joshi, a professor of industrial engineering.

Joshi explains, “We want to automate the decision process for manufacturing designs to get to ‘push button additive manufacturing’. The idea of the software is to make five-axis AM fully automated without the need for manual work or re-designs of a product.”

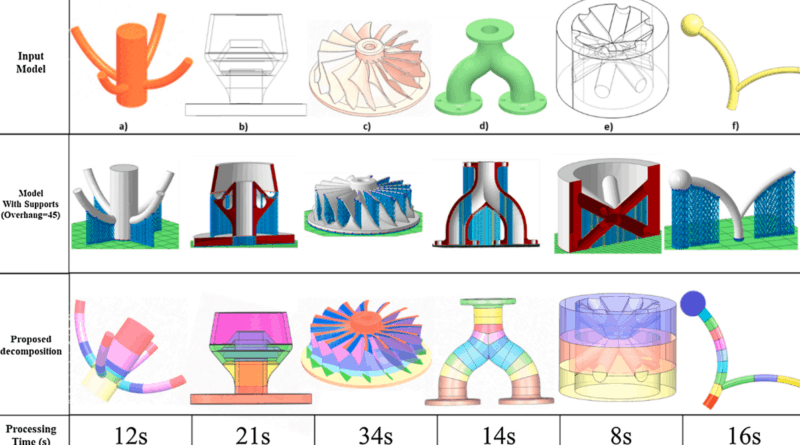

Xiao’s software works by determining a part’s individual sections and their orientations, which allows its algorithms to decide which portion of the component will be printed first and at what angle. Through this decomposition process, the part’s geometry is broken down into individual blocks, whereby each block is printable on top of the previous one without any support structures. As each section is printed in the predetermined order, the build plate reorients itself to set up the next step in the sequence, in a process akin to building with Lego blocks.

There will, of course, be geometries that are not printable without support structures. In these scenarios, the algorithm can inform the user as to how feasible their design is, allowing designers to make corrections and modify their geometries before committing to a print – further saving on costs.

Joshi explains, “With an algorithm, you don’t really need the expertise from the user because it’s in the software. Automation can help with trying out a bunch of different scenarios very quickly before you create anything on the machine.”

Xiao has already stated plans to further develop the research to be applicable to industrial metal 3D printing systems, as her key application areas are aerospace and automotive. She concludes, “Large metal components, using traditional additive manufacturing, can take days and waste lots of materials by using support structures. Additive manufacturing is very powerful, and it can make a lot of things due to its flexibility; however, it also has its disadvantages. There is still more work to do.”

Software programs designed to bridge the worlds of CAD and 3D printing can take many shapes and forms. Just last month, 3D printer manufacturer Stratasys announced a partnership with engineering software developer nTopology to streamline the Design for Additive Manufacturing (DfAM) process for jigs, fixtures, and other tooling. The partners have commenced work on the development of a series of accessible, customizable DfAM programs for their users, starting with the FDM Assembly Fixture Generator.

Elsewhere, at MIT’s Computer Science and Artificial Intelligence Laboratory, researchers recently developed a novel 3D design environment that enables users to digitally model both an object’s physical form and electronic function simultaneously. MorphSensor draws from both conventional CAD software and circuit building software to enable custom mechatronic components to be designed for 3D printing.

Source:https://3dprintingindustry.com