The Future of 3D Printers

Today every factory, every office, every school, every institute in various industries uses a 3D printer. Whether it be for casual use or industrial purposes the need to have a 3D printer is felt everywhere. 3D printing is considered to be among one of the many “future” technologies not only because it will be used in the future, but because it far ahead of many present technologies rendering them redundant.

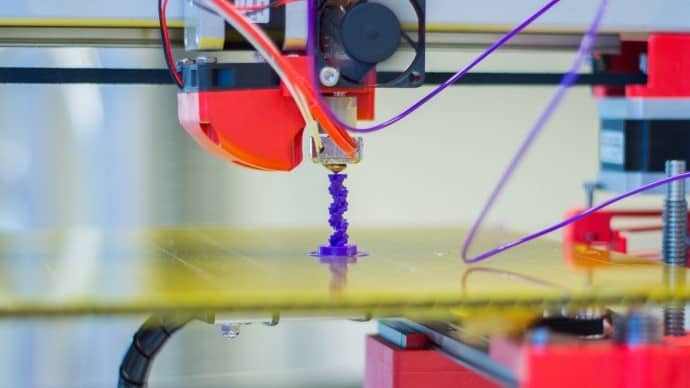

Different from regular 2D printing, 3D printing allows users to give a 3rd dimension to their creative but flat innovations. It allows a whole new array of possibilities where users can manufacture their own custom designed products sitting at home in their hand. 3D printing small projects such as balls or keychains is only a matter of hours including the design process and execution both.

Currently 3D printing is used mostly in the Robotics industry to create many parts which are lightweight yet sturdy and fairly cheap. Recently, the University of Maine has created the world’s largest 3D printed boat. They designed a 30 meter high 3D printer to use raw materials of biological origin such as cellulose from wood. Apparently the 3D printer was designed for rapid prototyping applications for civil, defense and infrastructure applications. In order to test the capabilities of this huge printer, the team created the 3D printed boat 3Dirigo. It was manufactured in just 72 hours from a mixture of plastic and wood cellulose.

3D printers are being used in other industries as well due to their light filament materials. New hyper-cars such as the McLaren 720S includes many 3D printed parts which allow the car to maintain a lighter weight while still getting the work done. Drones are being completely 3D printed at rapid rates to help deliver essential goods during pandemics. The cost of making a 3D printed drone is the same as an average delivery-boys monthly salary.

Other than the automobile industry other industries are also warming up and adapting to this technology. Currently an Israel based research center is developing 3D printed meat. Scientists are using plant developed organic material as filament in the 3D printer. They identified fats, blood and muscles to be the primary building blocks of meat, and are hence using those three main components from plants and organic sources to make a filament which can then be used as filament in 3D printers. They have begun testing of 3D printed Steak and are going to introduce it to potential consumers soon.

In conclusion it is safe to say that from 3D printed boats to food, much of the future is going to be dependent on 3D printed for manufacturing most products we use in our daily lives and its safe to speculate that in the next 5 years, every household will have their own 3D printer.

By OMOTEC Student – Sidharth Jain, JNIS IBDP 2022